A fannin kera kayayyaki daidai gwargwado, sassan granite suna tsaye a matsayin jarumai da ba a taɓa jin su ba waɗanda ke ƙarfafa daidaiton injunan zamani. Daga layukan samar da semiconductor zuwa dakunan gwaje-gwaje na metrology na zamani, waɗannan gine-ginen dutse na musamman suna ba da tushe mai ƙarfi da ake buƙata don ma'aunin nanoscale da ayyukan da suka dace. A ZHHIMG, mun shafe shekaru da yawa muna kammala fasaha da kimiyyar ƙirar sassan granite, muna haɗa fasahar gargajiya da ƙa'idodin injiniya na zamani don ƙirƙirar mafita waɗanda suka cika ƙa'idodin masana'antu mafi buƙata.

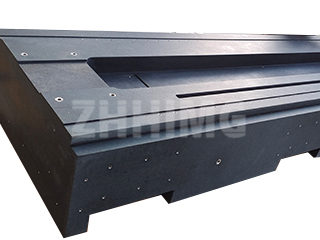

Tafiyar ƙirƙirar sassan granite masu inganci ta fara ne da zaɓin abu - shawara mai mahimmanci wacce ke shafar aikin samfurin ƙarshe kai tsaye. Injiniyoyinmu suna amfani da dutse mai launin baƙi na ZHHIMG® kawai, wani abu na musamman mai yawan kusan 3100 kg/m³ wanda ya fi nau'ikan granite na Turai da Amurka yawa a cikin kwanciyar hankali da halayen jiki. Wannan tsari mai yawa ba wai kawai yana ba da danshi na girgiza na musamman ba amma kuma yana tabbatar da ƙarancin faɗaɗa zafi, babban siffa don kiyaye daidaito a cikin yanayi daban-daban na muhalli. Ba kamar wasu masana'antun da ke yanke kusurwa ta amfani da madadin marmara ba, mun ci gaba da jajircewa ga wannan kayan aiki mai kyau wanda ke samar da kashin bayan amincin sassanmu.

Zaɓar kayan aiki kawai, duk da haka, shine kawai wurin farawa. Gaskiyar sarkakiyar ƙirar kayan dutse tana bayyana kanta a cikin daidaita buƙatun aiki da gaskiyar muhalli. Kowane ƙira dole ne ya yi la'akari da hulɗar da ke tsakanin kayan aikin da yanayin aikinsa, gami da canjin zafin jiki, matakan danshi, da kuma hanyoyin girgiza mai yuwuwa. Cibiyarmu mai girman m² 10,000 ta kula da zafin jiki da danshi (taron kula da zafin jiki da danshi akai-akai) an ƙera ta musamman don magance waɗannan ƙalubalen, tare da benaye siminti masu kauri mm 1000 da faɗin mm 500, zurfin mm 2000 waɗanda ke ƙirƙirar yanayi mafi kyau don kerawa da gwaji.

Daidaiton injina wani ginshiƙi ne na ingantaccen ƙirar sassan granite. Haɗa abubuwan da aka saka ƙarfe a cikin granite yana buƙatar haƙuri mai kyau don tabbatar da rarraba kaya yadda ya kamata da kuma watsa karfin juyi. Ƙungiyar ƙirarmu tana la'akari da kyau ko za a iya maye gurbin kayan ɗaure na gargajiya da tsarin da ya fi dacewa da tsagi, suna kimanta daidaito tsakanin daidaiton tsari da yuwuwar masana'antu. Halayen saman suna buƙatar kulawa mai ƙarfi - sau da yawa dole ne a kiyaye lanƙwasa har zuwa matakan micrometer, yayin da saman ɗaukar iska ke buƙatar dabarun ƙarewa na musamman don cimma santsi da ake buƙata don motsi mara gogayya.

Wataƙila mafi mahimmanci, ƙirar kayan aikin granite na zamani dole ne ya yi hasashen takamaiman buƙatun aikace-aikacen da aka yi niyya. Misali, tushe don injin duba semiconductor, yana fuskantar buƙatu daban-daban fiye da farantin saman dakin gwaje-gwaje na metrology. Injiniyoyinmu suna haɗin gwiwa da abokan ciniki don fahimtar ba kawai buƙatun girma na nan take ba har ma da tsammanin aiki na dogon lokaci. Wannan hanyar haɗin gwiwa ta haifar da abubuwan da ke ba da muhimmiyar rawa a aikace-aikace tun daga tsarin micromachining na laser zuwa injunan aunawa masu tasowa (CMMs).

Tsarin kera kansa yana wakiltar haɗuwar fasahar gargajiya da fasahar zamani. Cibiyarmu tana ɗauke da injunan niƙa guda huɗu na Taiwan Nante, kowannensu ya wuce dala $500,000, waɗanda ke da ikon sarrafa kayan aiki har zuwa mm 6000 a tsayi tare da daidaiton sub-micron. Duk da haka tare da wannan kayan aikin na zamani, za ku sami ƙwararrun ma'aikata waɗanda ke da ƙwarewa sama da shekaru talatin waɗanda za su iya cimma daidaiton nanoscale ta hanyar lapping hannu - ƙwarewar da muke kira "masana'antar metrology." Wannan haɗin tsoffin da sababbi yana ba mu damar magance yanayin sassa mafi rikitarwa yayin da muke kiyaye mafi girman ma'aunin daidaito.

Tabbatar da inganci yana ratsa kowane mataki na tsarin ƙira da ƙera mu. Mun saka hannun jari sosai wajen ƙirƙirar tsarin aunawa mai cikakken tsari wanda ya haɗa da ma'aunin Dial na Jamusanci na Mahr (ma'aunin bugun kira) tare da ƙudurin 0.5 μm, tsarin aunawa mai daidaitawa na Mitutoyo, da kuma na'urorin auna laser na Renishaw. Kowace daga cikin waɗannan kayan aikin ana yin su akai-akai ta hanyar Cibiyoyin Jinan da Shandong Metrology, wanda ke tabbatar da bin diddigin ƙa'idodin ƙasa. Wannan alƙawarin ga ƙwarewar aunawa ya yi daidai da falsafar kamfaninmu: "Idan ba za ku iya aunawa ba, ba za ku iya samar da shi ba."

Sadaukarwarmu ga daidaito da inganci ya sa mu haɗin gwiwa da shugabannin masana'antu a duk faɗin duniya, ciki har da GE, Samsung, da Bosch, da kuma manyan cibiyoyin bincike kamar Jami'ar Ƙasa ta Singapore da Jami'ar Stockholm. Waɗannan haɗin gwiwar suna ci gaba da tura mu don inganta hanyoyin ƙira da kuma bincika sabbin iyakoki a cikin fasahar granite ta ZHHIMG. Ko muna haɓaka wani matakin ɗaukar iska na musamman ga masana'antar semiconductor ta Turai ko farantin saman daidaito ga dakin gwaje-gwajen metrology na Amurka, manyan ƙa'idodin kimiyyar kayan abu, injiniyan injiniya, da kula da muhalli su ne jagororinmu.

Yayin da masana'antu ke ci gaba da tafiya ba tare da tsayawa ba zuwa ga daidaito mafi girma, rawar da sassan granite masu daidaito za su taka rawa kawai. Waɗannan gine-gine masu ban mamaki suna cike gibin da ke tsakanin duniyar injina da ta dijital, suna samar da dandamali mai dorewa wanda fasaharmu mafi ci gaba ta dogara da shi. A ZHHIMG, muna alfahari da ci gaba da gadon fasahar granite masu daidaito yayin da muke rungumar sabbin abubuwa da za su ayyana makomar masana'antu. Takaddun shaida na ISO 9001, ISO 45001, ISO 14001, da CE suna tsaye a matsayin shaida ga jajircewarmu ga inganci, aminci, da alhakin muhalli - dabi'u waɗanda aka haɗa a cikin kowane ɓangaren da muke tsarawa da samarwa.

A ƙarshe, nasarar ƙirar sassan granite ta fi game da cika takamaiman bayanai; yana game da fahimtar zurfin manufar da ke bayan kowace ma'auni, kowace haƙuri, da kowace ƙarewar saman. Yana game da ƙirƙirar mafita waɗanda ke ba abokan cinikinmu damar tura iyakokin abin da zai yiwu a cikin kera daidai. Yayin da muke duban gaba, muna ci gaba da himma don haɓaka kimiyyar ƙirar sassan granite, tare da tabbatar da cewa waɗannan mahimman abubuwan suna ci gaba da tallafawa sabbin abubuwan fasaha da ke tsara duniyarmu.

Lokacin Saƙo: Nuwamba-03-2025