Ana amfani da kayan aikin injin CNC (mai sarrafa lambar kwamfuta) a masana'antu daban-daban kamar masana'antu, jiragen sama, motoci, da sauransu. Ana amfani da waɗannan injunan don yanke, siffantawa, da sassaka kayan aiki kamar ƙarfe, filastik, itace, da granite. Injunan CNC suna buƙatar tushe mai ƙarfi don samar musu da kwanciyar hankali da daidaito, shi ya sa ake amfani da tushen granite a matsayin muhimmin sashi a cikin kayan aikin injin CNC.

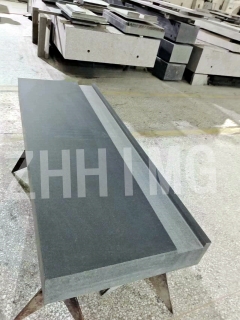

An san dutse mai daraja saboda kyakkyawan daidaiton girma da juriya ga nakasa, wanda hakan ya sa ya zama kayan aiki mai kyau don amfani da shi wajen gina tushen kayan aikin injin. Kwanciyar granite yana tabbatar da cewa motsin injin yayin aikin yankewa bai shafi daidaiton yankewa ba. Babban tauri da tsarin granite iri ɗaya suna tabbatar da ƙarancin karkacewa da kwanciyar hankali ko da a ƙarƙashin yanayin zafi da matsin lamba mai tsanani.

Amfani da granite a matsayin tushe kuma yana ba da babban matakin damping ga injunan CNC. Abubuwan da ke ɗaukar girgiza na halitta na granite suna ba da damar injuna su yi aiki a cikin babban gudu ba tare da girgiza ko tsayawa kwatsam ba, wanda ke inganta daidaito da daidaito. Girgizar da tsarin yankewa ke haifarwa na iya haifar da motsi mara so a cikin injin, amma saboda halayen damping na granite, waɗannan girgizar suna raguwa ko kuma an kawar da su gaba ɗaya.

Bugu da ƙari, tushen granite yana sa kayan aikin injin CNC su kasance daidai kuma daidai wurin aiki. Granite yana da ƙarancin kauri da kuma babban lanƙwasa, wanda ke nufin cewa saman granite ɗin ya yi daidai har zuwa cikin 'yan microns. Lokacin da aka sanya gadon injin yadda ya kamata a saman tushen granite, yana ba injin damar samun wurin aiki mai ƙarfi da daidaito. Wannan yana tabbatar da cewa kayan aikin injin sun yanke daidai da takamaiman buƙatun da ake buƙata.

Wani fa'idar amfani da granite a tushen injunan CNC shine yana ba da kyakkyawan juriya ga sinadarai da tsatsa. Granite yana jure wa yawancin acid, tushe, da abubuwan narkewa, wanda hakan ya sa ya zama abu mafi dacewa don amfani a cikin mawuyacin yanayi. Wannan yana da mahimmanci a masana'antu inda ake amfani da sinadarai da mai akai-akai, domin yana rage yuwuwar tsatsa da gurɓatawa a saman kayan aikin injin.

A ƙarshe, tushen granite muhimmin sashi ne a cikin kayan aikin injin CNC. Yana tabbatar da kwanciyar hankalin injin yayin aikin yankewa, yana rage girgiza, yana samar da yanayin aiki mai kyau, kuma yana inganta daidaito da daidaito. Fa'idodin amfani da granite a matsayin tushen injin yana sa ya shahara a masana'antu daban-daban na masana'antu kuma yana ba da damar kayan aikin injin su yi aiki a manyan matakan inganci da daidaito.

Lokacin Saƙo: Maris-26-2024