CMM (Injin aunawa mai daidaitawa) na'urar aunawa ce mai inganci kuma mai daidaito wacce ake amfani da ita a masana'antu kamar su sararin samaniya, motoci, da likitanci. Duk da cewa akwai nau'ikan CMM daban-daban, ɗaya daga cikin kayan da aka fi amfani da su don tushen CMM shine granite. Granite kyakkyawan zaɓi ne na kayan abu saboda yana da tauri, tsayayye, kuma yana ba da saman da aka daidaita don CMM don aunawa daga ciki.

Duk da haka, shigar da CMM a kan tushen granite bai isa ya tabbatar da daidaiton ma'auni mafi kyau ba. Akwai abubuwa da yawa da ya kamata a yi la'akari da su domin tabbatar da cewa CMM yana aiki mafi kyau. A cikin wannan labarin, za mu tattauna wasu muhimman abubuwan da ya kamata a yi la'akari da su yayin shigar da CMM a kan tushen granite don inganta daidaiton ma'auni.

1. Kula da Zafin Jiki

Kula da yanayin zafi yana ɗaya daga cikin muhimman abubuwan da ya kamata a yi la'akari da su. Granite yana da yawan faɗaɗa yanayin zafi, wanda ke nufin yana iya faɗaɗawa da kuma yin ƙunci idan aka yi la'akari da canje-canje a yanayin zafi. Saboda haka, yana da mahimmanci a kiyaye yanayin zafi mai kyau a ɗakin da CMM yake. Ko da ƙananan canjin yanayin zafi na iya sa granite ya faɗaɗa ko ya yi ƙunci, wanda zai haifar da kurakuran aunawa. Don guje wa wannan, ya kamata a sarrafa yanayin zafin ɗakin, kuma CMM ya kamata a rufe shi daga duk wani canjin yanayin zafi na waje.

2. Kula da Girgiza

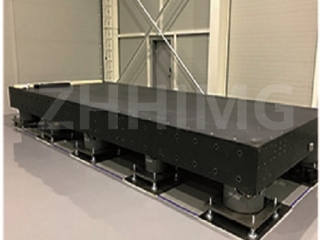

Kula da girgiza wani muhimmin abu ne don tabbatar da daidaiton aunawa. Granite kyakkyawan abin da ke rage girgiza ne, amma har yanzu yana da sauƙin kamuwa da girgiza daga tushen waje kamar sauran injuna, hanyoyi na kusa, ko ma zirga-zirgar ƙafa. Waɗannan girgiza na iya sa tushen granite ya motsa, wanda ke haifar da kurakuran aunawa. Don rage tasirin girgizar waje, ya kamata a sanya CMM a wuri mara girgiza, kuma duk wani tushen girgizar waje ya kamata a ware shi ko a kare shi.

3. Daidaita matsayi

Samun tushen granite mai daidaito yana da matuƙar muhimmanci don auna daidai. Lokacin shigar da CMM akan tushen granite, ya kamata a daidaita tushen da daidaito mai girma. Tsarin daidaita matakin yana da mahimmanci domin ko da ƙaramin karkacewa na iya haifar da kurakuran aunawa. Saboda haka, ana ba da shawarar a yi matakin ta amfani da matakan daidaito kuma a tabbatar da shi ta amfani da CMM da kanta.

4. Shigarwa

Wani muhimmin abin la'akari kuma shi ne shigar da CMM a kan tushen dutse. Ya kamata a shigar da CMM cikin kulawa da daidaito, don guje wa duk wani kuskure ko lalacewa. Ya kamata ƙwararru masu ƙwarewa da ƙwarewa su gudanar da tsarin shigarwa don tabbatar da cewa an shigar da CMM daidai.

5. Kulawa

Kula da CMM yana da mahimmanci don tabbatar da ingantaccen aiki da daidaiton aunawa. Kula da injin da tushen granite akai-akai zai tabbatar da cewa CMM yana aiki da kyau. Ana buƙatar maye gurbin sassan da suka lalace ko suka lalace cikin sauri, kuma ana buƙatar a duba tushen granite akai-akai. Dubawa akai-akai da hanyoyin kulawa na iya hana buƙatar gyare-gyare masu tsada da kuma rage tasirin da ke kan daidaiton aunawa.

Kammalawa

A taƙaice, tushen granite na CMM yana da matuƙar muhimmanci don daidaiton ma'auni. Duk da haka, shigar da CMM akan tushen granite bai isa ba don tabbatar da daidaiton ma'auni mafi kyau. Ya kamata a yi la'akari da muhimman abubuwa da dama, ciki har da sarrafa zafin jiki, sarrafa girgiza, daidaita matakin, shigarwa, da kulawa. Ta hanyar la'akari da waɗannan abubuwan, masana'antun za su iya tabbatar da cewa CMM ɗinsu suna aiki a mafi kyawun su, kuma ana ɗaukar ma'auni daidai gwargwado.

Lokacin Saƙo: Afrilu-01-2024