A masana'antar sarrafa gilashi, daidaito da kwanciyar hankali na kayan aikin yanke gilashi kai tsaye suna tantance ingancin samfura da ingancin samarwa. Tushen dutse suna taka muhimmiyar rawa a cikin kayan aikin yanke gilashi, galibi saboda halaye na musamman da nagari.

Kwanciyar hankali mai kyau yana tabbatar da daidaiton yankewa

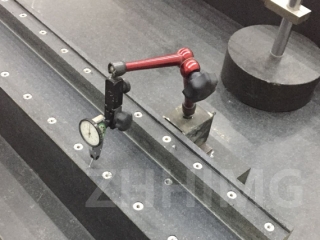

Yanke gilashi yana da matuƙar buƙatar daidaito. Ko da ƙaramin karkacewa zai iya haifar da goge samfurin. An kafa tushen granite a tsawon lokaci mai tsawo, tare da tsari mai yawa da daidaito. Matsakaicin faɗaɗa zafi yana da ƙasa sosai, kawai (4-8) ×10⁻⁶/℃, kuma girmansa ba ya canzawa lokacin da zafin ya bambanta. A lokacin aikin yanke gilashi, zafin da aka samu ta hanyar aikin kayan aiki da canjin yanayin yanayin bita ba zai haifar da gurɓataccen zafi na tushen granite ba. Kullum yana iya samar da tallafi mai karko da aminci ga na'urar yankewa, yana tabbatar da daidaiton wurin da kayan aikin yanke ko katakon laser suke. Gilashin da aka yanke yana da gefuna masu kyau da daidaito, yana inganta yawan amfanin samfuran sosai.

Ƙarfin tauri yana tsayayya da tasirin ƙarfi na waje

Lokacin da kayan aikin yanke gilashin ke aiki, hulɗar da ke tsakanin sassan yanke da gilashin zai haifar da wani ƙarfin tasiri, kuma a lokaci guda, motsin kayan aikin da kansa zai haifar da girgiza. Granite yana da tauri a cikin laushi kuma yana da matuƙar tauri. Taurinsa na iya kaiwa 6-7 akan sikelin Mohs kuma yana da ƙarfin matsi mai yawa. Wannan yana bawa tushen granite damar jure wa ƙarfi daban-daban na waje cikin sauƙi yayin aikin yankewa kuma ba shi da yuwuwar lalacewa ko lalacewa. Idan aka kwatanta da wasu sansanonin ƙarfe waɗanda za su iya fuskantar lalacewar gajiya a ƙarƙashin ƙarfin waje na dogon lokaci da akai-akai, sansanonin granite, tare da ƙarfinsu mai ƙarfi, koyaushe suna iya kiyaye tsari mai ƙarfi, yana tabbatar da dorewar aikin kayan aiki na dogon lokaci da rage kulawa da lokacin aiki da rashin aiki da matsalolin tushe ke haifarwa.

Kyakkyawan aikin damping yana rage tsangwama na girgiza

Girgiza yana ɗaya daga cikin muhimman abubuwan da ke shafar daidaiton yanke gilashi. Idan girgizar da aka samu yayin aikin kayan aikin ba za a iya rage ta ba cikin lokaci, zai sa kayan aikin yanke ko hasken laser su girgiza, wanda ke haifar da matsaloli kamar saman yankewa mai kauri da layukan yankewa marasa daidaito. Granite yana da kyakkyawan aikin damfara. Tsarin ma'adinai mai rikitarwa da ƙananan ramuka a ciki suna kama da masu shaƙar girgiza na halitta. Lokacin da aka aika girgizar zuwa tushen granite, waɗannan tsare-tsare da ramuka na iya canza kuzarin girgiza zuwa makamashin zafi da sauri kuma su wargaza shi, wanda hakan ke rage tsangwama na girgiza a kan tsarin yankewa. Misali, a cikin kayan aikin yanke gilashin laser mai sauri, tushen granite na iya danne girgizar kan laser yadda ya kamata, yana tabbatar da cewa hasken laser yana aiki a kan saman gilashin kuma yana samun sakamako mai kyau da inganci.

Kyakkyawan juriya ga lalacewa yana ƙara tsawon rayuwar kayan aikin

A lokacin aiki na dogon lokaci na kayan aikin yanke gilashi, tushen zai haifar da wasu gogayya da kayan aikin yanke gilashi, kayan gilashi, da sauransu. Granite yana da juriya mai kyau saboda tsananin tauri da tsarinsa mai yawa. Misali, an yi shi da granite kuma yana iya jure gogayya da ake samu sakamakon sanya gilashin akai-akai da motsi na kayan aikin yanke, kuma ba shi da yuwuwar samun matsaloli kamar lalacewa da karce. Wannan ba wai kawai yana tabbatar da lanƙwasa saman tushe ba kuma yana kiyaye daidaiton kayan aikin, har ma yana tsawaita rayuwar ginin har ma da dukkan kayan aikin yanke gilashi, wanda ke rage farashin sabunta kayan aiki na kamfanoni.

Ba shi da maganadisu, yana guje wa tsangwama ta hanyar lantarki ga tsarin yankewa

A wasu kayan aikin yanke gilashi na zamani, ana amfani da kayan lantarki da na'urori masu auna daidai don sarrafa daidaiton yankewa da matsayinsa. Mai yiwuwa maganadisu na tushen ƙarfe na iya haifar da tsangwama ta lantarki ga waɗannan na'urorin lantarki, wanda ke shafar aikinsu na yau da kullun da daidaiton watsa sigina. A gefe guda kuma, dutse abu ne da ba na ƙarfe ba wanda ba shi da maganadisu kuma ba zai haifar da tsangwama ta lantarki ga tsarin lantarki da ke cikin kayan ba. Wannan yana bawa kayan aikin yanke gilashi damar aiki a cikin yanayin lantarki mai karko, yana tabbatar da isar da siginar sarrafawa daban-daban daidai lokacin yankewa, da kuma ƙara haɓaka daidaiton yankewa da amincin aikin kayan aiki.

A ƙarshe, tushen duwatsun granite, tare da kyakkyawan kwanciyar hankali, ƙarfin juriya, kyakkyawan aikin damfara, juriya mai kyau da rashin maganadisu, sun zama zaɓi mafi kyau ga kayan aikin yanke gilashi, suna ba da garanti mai ƙarfi ga masana'antar sarrafa gilashi don cimma ingantaccen samarwa da inganci.

Lokacin Saƙo: Mayu-19-2025