A duniyar masana'antu da tsarin auna daidaito, kwanciyar hankali shine komai. Ko a cikin kayan aikin semiconductor, injin CNC mai daidaito, ko tsarin duba gani, har ma da rawar jiki na matakin micron na iya yin illa ga daidaito. Nan ne Granite Air Bearing Stages ke yin fice, yana ba da kwanciyar hankali da aminci mara misaltuwa ga aikace-aikacen masana'antu masu inganci.

Matsayin Granite a Matakan Daidaito

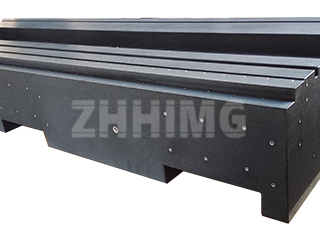

Granite ba wai kawai kayan aiki ne mai inganci ba—shi ne ginshiƙin injiniya mai matuƙar daidaito. Baƙar fata na ZHHIMG® da ake amfani da shi a matakan ɗaukar iska yana da yawan gaske (~3100 kg/m³) da kuma kyakkyawan kwanciyar hankali, wanda hakan ya sa ya fi kayan yau da kullun kamar aluminum, ƙarfe, ko ma wasu granites da aka shigo da su. Waɗannan halayen zahiri suna rage nakasar da ke ƙarƙashin kaya, suna rage faɗaɗa zafi, kuma suna samar da tasirin girgiza-damtse wanda yake da mahimmanci ga matakan daidaito.

Ba kamar ƙarfe ba, granite ba ya lanƙwasawa ko lanƙwasawa cikin sauƙi a lokacin damuwa. Tsarinsa na lu'ulu'u iri ɗaya yana tabbatar da tauri iri ɗaya a duk faɗin dandamalin, yana ba da damar kayan aikin daidaito su ci gaba da daidaitawa akan lokaci. Bugu da ƙari, halayen danshi na halitta na granite suna sha girgizar muhalli, suna ƙara inganta kwanciyar hankali a matakin.

Bearings na Iska: Daidaito mara ƙarfi

Haɗa bearings na iska a kan tushen dutse yana ɗaukar kwanciyar hankali zuwa wani sabon mataki. Bearings na iska suna ƙirƙirar siriri, fim iri ɗaya na iska mai matsi tsakanin dandamali da hanyar jagora, wanda ke ba da damar motsi mara shinge. Wannan yana kawar da tasirin zamewa da sanda kuma yana rage lalacewa, wanda ya zama ruwan dare a cikin bearings na injiniya na gargajiya. Sakamakon shine motsi mai santsi, mara girgiza wanda yake da mahimmanci ga aikace-aikacen da ke buƙatar daidaiton matakin nanometer.

Idan aka ɗora shi a kan tushen granite, bearings na iska suna amfana daga lanƙwasa da tauri na kayan. Granite yana tabbatar da cewa gibin iska ya kasance iri ɗaya, yana hana karkatarwa ko rarraba kaya mara daidaituwa. Wannan haɗin gwiwa tsakanin granite da fasahar bearing na iska shine dalilin da ya sa ake ɗaukar ZHHIMG® Granite Air Bearing Stages a matsayin ma'aunin daidaito a cikin kayan aiki masu matuƙar daidaito.

Kwanciyar Hankali da Fa'idodin Muhalli

Canje-canjen zafin jiki na iya yin tasiri sosai ga matakan daidaito, musamman a cikin yanayin daidaito mai yawa kamar kayan aikin semiconductor ko dakunan gwaje-gwajen auna haske. Ƙarancin faɗuwar zafi na granite yana rage canje-canjen girma tare da canjin zafin jiki, yana kiyaye daidaiton matakin da daidaito. Idan aka haɗa shi da bita na muhalli mai sarrafawa, waɗannan matakan suna ba da aiki mai daidaito koda a cikin yanayi mai ƙalubale.

Bugu da ƙari, juriyar granite ga tsatsa, lalacewa, da gajiya yana tabbatar da aminci na dogon lokaci, koda a cikin mawuyacin yanayi na masana'antu. Ba kamar matakan ƙarfe waɗanda ke buƙatar kulawa akai-akai ba, matakan ɗaukar iska na granite suna kiyaye daidaiton su tsawon shekaru na ci gaba da aiki.

Aikace-aikace a Faɗin Masana'antu

Haɗin keɓaɓɓen halayen zahiri na granite da fasahar ɗaukar iska ya sa waɗannan matakan suka dace da aikace-aikace iri-iri:

-

Kayan Aikin Semiconductor: Duba Wafer, lithography, da kuma tsarin rufewa

-

Injinan CNC masu daidaito: Injin niƙa mai inganci, haƙowa, da injin laser

-

Tsarin Na'urar Dubawa: Injinan aunawa masu daidaitawa (CMM), masu auna bayanai, da tsarin AOI

-

Bincike da Ci Gaba: Jami'o'i da cibiyoyi suna gudanar da gwaje-gwajen nano-scale

A cikin kowane aikace-aikacen, kwanciyar hankali da matakan ɗaukar iska na granite ke bayarwa kai tsaye yana fassara zuwa ga daidaiton ma'auni mafi girma, ingantaccen ingancin samarwa, da rage kurakuran aiki.

Me yasa Matakan Haɗakar Iska na Granite ZHHIMG® suka fi fice

ZHHIMG® yana amfani da ƙwarewar shekaru da yawa a fannin sarrafa granite da injiniyan da ya dace. Matakan granite ɗinmu an niƙa su kuma an haɗa su zuwa matakin nanometer mai faɗi, kuma kowane matakin ɗaukar iska ana daidaita shi da kyau ta amfani da kayan aikin aunawa na duniya, gami da na'urorin auna laser da matakan lantarki. Wannan alƙawarin ga daidaito yana tabbatar da cewa kowane matakin ZHHIMG® yana ba da kwanciyar hankali, aminci, da aiki mafi girma.

A taƙaice, daidaiton matakan ɗaukar iska na granite ba wai kawai ikirarin tallatawa ba ne - sakamakon kayan da aka ƙera da kyau, ƙirar ɗaukar iska mai zurfi, da kuma ƙwarewar da ta dace. Ga masana'antu da ke buƙatar daidaito sosai, aiki mai maimaitawa, da aminci na dogon lokaci, ZHHIMG® Granite Air Bearing Stages sun kafa mizani na duniya.

Lokacin Saƙo: Satumba-26-2025