A duniyar gasa ta masana'antar Mold Manufacturing - musamman ga molds na allura, mashin dinki, da kuma tsarin siminti da ake amfani da su a cikin motoci, na'urorin likitanci, da kuma samar da na'urorin lantarki - gibin kuskure ya ɓace. Mold mara aibi shine garantin miliyoyin samfuran ƙarshe masu kyau. Tsarin yin mold gaba ɗaya, daga injin sarrafa lambobi na kwamfuta na farko (CNC) zuwa haɗakar ƙarshe, ya dogara ne akan ikon tabbatarwa akai-akai da sanya sassan tare da daidaiton matakin micron. Wannan buƙatar tushe ta bayyana dalilin da yasa Precision Granite Surface Plate ba kawai kayan aiki bane, amma mahimman bayanai na ma'auni ga masana'antar.

Matsayin da dandamalin granite ke da shi a wannan fanni ya wuce duba saman da aka yi kawai; yana aiki a matsayin babban mai daidaita daidaiton lissafi, yana ba injiniyoyi masu inganci damar tabbatar da daidaiton girman sassan mold masu mahimmanci, yana tabbatar da musayar abubuwa da kuma haɗuwa mara aibi tsakanin rabin mold.

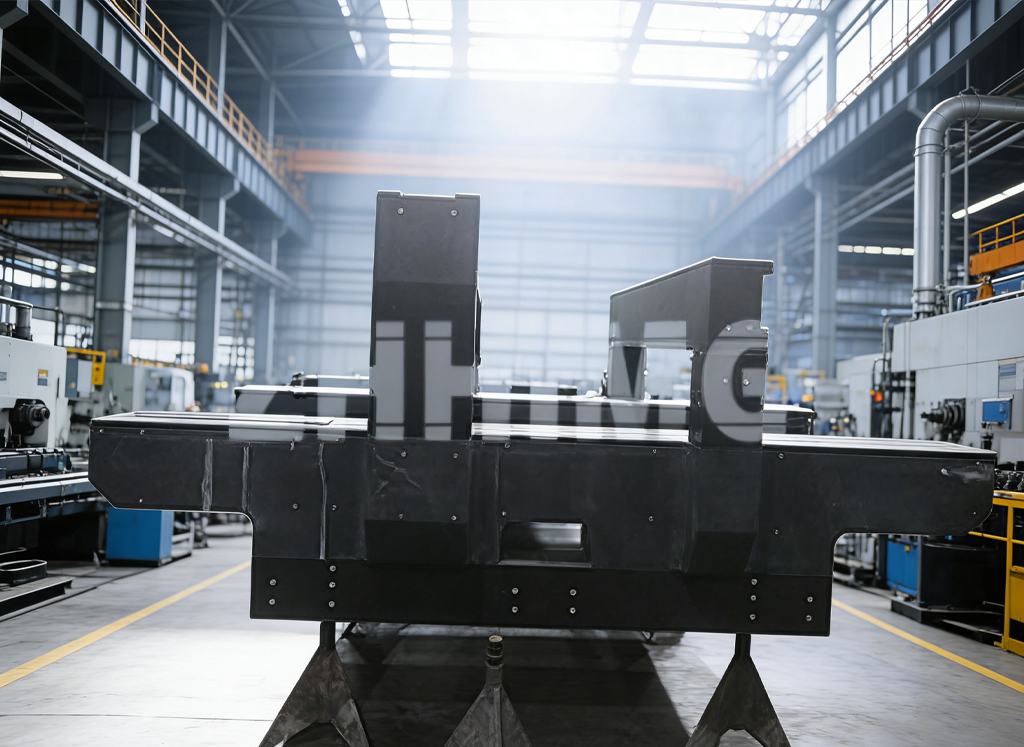

Kalubalen Kera Mold: Ingancin Geometric a Babban Sauri

Abubuwan da ke cikin mold, kamar ramuka, tsakiya, da kuma zamewar hadaddun siffofi, galibi suna da siffofi masu rikitarwa na 3D, juriya mai tsauri, da kuma saman da aka goge sosai. Duk wani gazawa a cikin tsarin mold—ko dai rashin daidaito ne, rashin daidaituwa, ko zurfin da bai dace ba—zai haifar da lahani kai tsaye a kowane ɓangare na gaba da aka samar, wanda zai haifar da asarar samarwa mai tsanani.

Tushen aunawa na gargajiya da aka yi da ƙarfe ko ƙarfe siminti suna fama don kiyaye kwanciyar hankali da ake buƙata saboda abubuwa kamar damuwa da ta rage, amsawar zafi, da rashin isasshen rage girgiza. Masu yin mold suna buƙatar kayan aikin metrology wanda ke ba da:

-

Cikakken Faɗi: Tsarin tunani mai inganci wanda za a iya duba dukkan tsayi, zurfin, da kusurwoyi a kai.

-

Kwanciyar Girma: Wani abu da ba ya shafar canjin yanayin zafi na benen bitar.

-

Keɓewar Girgiza: Tushe mai ƙarfi wanda ke hana rikice-rikicen muhalli shafar kayan aikin aunawa masu mahimmanci kamar alamun bugun kira, matakan lantarki, ko na'urorin bincike na CMM.

Muhimmancin Aikin Granite: Daidaito da Haɗawa

DaidaitoFarantin Dutse na Dutsemagance waɗannan ƙalubalen ta hanyar manyan ayyuka guda biyu a shagon mold: Duba Daidaiton Mold da Matsayin Tushe Mai Muhimmanci.

1. Duba Daidaiton Mold: Gaskiyar Bayani game da Inganci

Lokacin da ake duba sassa daban-daban da suka ƙunshi saitin mold, farantin granite yana ba da takardar shaida, ba tare da wata shakka ba:

-

Tabbatar da Girma: Granite mai yawan yawa, kamar ZHHIMG® Black Granite (tare da yawan kusan 3100 kg/m³), yana ba da ƙarfi mai kyau, yana tabbatar da cewa farantin bai karkace ba a ƙarƙashin nauyin manyan tushe ko manyan mold. Wannan yana bawa ma'aikatan tabbatar da inganci damar tabbatar da daidaito, murabba'i, da lanƙwasa daidai ta amfani da ma'aunin tsayi, matakan lantarki, da tubalan ma'auni. Babban damƙar ciki na kayan yana ƙara tabbatar da cewa girgizar muhalli ba ta tsoma baki ga karatun aunawa mai mahimmanci ba.

-

Nassoshi na gani da CMM: Farantin shine ginshiƙin da aka wajabta wa duk kayan aikin da aka yi amfani da su wajen gano daidaiton Mold, gami da Injinan Aunawa Masu Daidaito (Kayan Aikin CMM), tsarin gani, da kuma na'urorin dubawa na musamman. Daidaiton tushen granite kai tsaye yana nuna daidaiton CMM gaba ɗaya, wanda hakan ya sa amfani da faranti masu takardar shaida na Grade 00 ko kuma waɗanda aka daidaita ba za a iya yin sulhu a kansu ba don aikin mold mai jurewa sosai.

-

Rashin Ingancin Zafi Don Inganci: Yayin da sassan mold ɗin kansu ke sanyi daga tsarin injin CNC, suna raguwa. Ƙananan Coefficient na Faɗaɗa Zafi (CTE) na granite yana tabbatar da cewa tushen tunani da kansa ya kasance daidai, yana samar da dandamali mai ƙarfi don bin diddigin da auna canje-canjen girma da suka shafi sanyaya daidai.

2. Matsayin Tushe da Haɗa Kayan Aiki: Cikakkiyar Gine-gine

Ingancin mold a ƙarshe ana tantance shi ta hanyar yadda abubuwan da ke cikinsa masu rikitarwa—ƙwayoyin halitta, ramuka, masu gudu, da fil ɗin ejector—suke daidaita yayin haɗa su. Farantin granite yana sauƙaƙa wannan muhimmin mataki:

-

Nassoshi Don Daidaita Daidaito: A matakan ƙarshe na haɗa mold, sau da yawa ana sanya sassan na ɗan lokaci a kan Dandalin Granite don duba daidaiton tsaye da na gefe kafin a fara bolting na ƙarshe. Ana amfani da Abubuwan Granite na musamman kamar murabba'ai, layi ɗaya, da tubalan V, waɗanda aka niƙa daidai da daidaiton sub-micron kamar farantin da kansa, don riƙe sassa masu rikitarwa a tsaye ko a layi ɗaya da datum plane, don tabbatar da haɗuwa mara lahani na rabin mold guda biyu.

-

Gogewa da Sanyawa: Ga tsofaffin molds ko na musamman waɗanda ke buƙatar gogewa da hannu ko haɗawa don cimma daidaiton taɓawa, farantin granite yana ba da kyakkyawan saman ma'auni don canja wurin manyan tabo zuwa ga ɓangaren mold ta amfani da mahaɗin shuɗi. Tsabta da taurin kayan suna tabbatar da cewa tsarin canja wurin yana da tsabta kuma daidai.

-

Tushen Gyaran Na Musamman: Bayan faranti na yau da kullun, ana amfani da Tsarin Injin Granite da tushe na musamman a matsayin dandamali na hawa don daidaita jigs ɗin haɗuwa. Waɗannan Taro na Granite na musamman suna ba da tsari mai ƙarfi wanda ke tsayayya da warpage da girgiza, yana ba masu haɗa kayan haɗin damar cimma juriyar tarin abubuwa da ake buƙata don manyan ramuka da ƙira masu matakai da yawa.

Bambancin ZHHIMG®: Abokin Hulɗa a Yin Mold Mai Daidaito

Ga masana'antar da sauri da daidaito suke da matuƙar muhimmanci, zaɓiMai ƙera Granite mai daidaitotare da iko na duniya da ƙarfin da ba a iya misaltawa ba shine mabuɗin. ZHONGHUI Group (ZHHIMG®) yana ɗaukaka matsayin Kayan Aikin Granite Metrology ta hanyar:

-

Ingantaccen Inganci: A matsayin kamfani ɗaya tilo a masana'antar da ke riƙe da ISO 9001, ISO 45001, IS a lokaci guda

14001, da takaddun shaida na CE, muna nuna sadaukarwa ta tsari ga inganci wanda ya dace da mafi girman ƙa'idodi da sarkar samar da kayayyaki ta masana'antar mold ke buƙata.

14001, da takaddun shaida na CE, muna nuna sadaukarwa ta tsari ga inganci wanda ya dace da mafi girman ƙa'idodi da sarkar samar da kayayyaki ta masana'antar mold ke buƙata. -

Ma'aunin Masana'antu Mara Kwarewa: Ikonmu na sarrafa manyan sassan granite - gami da na'urori guda ɗaya har zuwa tan 100 - da kuma layukan samar da kayayyaki masu sauri suna tabbatar da cewa za mu iya samar da manyan, hadaddun, da kuma manyan Granite Bases da masana'antun kera motoci da na'urorin lantarki na duniya ke buƙata ba tare da wata matsala ba.

-

Neman Kammalawa: Tare da jajircewar, "Babu yaudara, Babu ɓoyewa, Babu yaudara," da kuma manufofin inganci, "Kasuwancin daidaito ba zai iya zama mai wahala ba," kowane dandamali an kammala shi a cikin Taron Zaman Lafiya da Danshi Mai Tsayi na 10,000 m², yana tabbatar da daidaitonsa kafin ya isa wurin aikin ku.

Sassauƙan tsarin yin mold na zamani yana buƙatar kayan aiki masu sauƙi, karko, kuma abin dogaro. Faranti na Surface na Precision Granite shine kayan aikin da ke samar da gaskiyar lissafi da ake buƙata don canza ƙirar dijital zuwa cikakkiyar jiki, yana tabbatar da inganci da tsawon rai na kowace mold da aka samar.

Lokacin Saƙo: Disamba-16-2025