Mafita Masana'antu na Ultra Precision

-

Tallafin da ba za a iya cirewa ba

Matsayin farantin saman don farantin saman: Farantin saman Granite da Daidaiton ƙarfe na Cast. Ana kuma kiransa Tallafin ƙarfe na Integral, Tallafin ƙarfe da aka welded…

An yi shi ta amfani da kayan bututun murabba'i tare da mai da hankali kan kwanciyar hankali da sauƙin amfani.

An tsara shi ne domin a kiyaye daidaiton da ke cikin Surface Plate na dogon lokaci.

-

Teburin Girgiza na gani

Gwaje-gwajen kimiyya a cikin al'ummar kimiyya ta yau suna buƙatar ƙarin lissafi da ma'auni daidai. Saboda haka, na'urar da za a iya ware ta daga muhallin waje da tsangwama tana da matuƙar muhimmanci don auna sakamakon gwajin. Tana iya gyara sassa daban-daban na gani da kayan aikin daukar hoto na microscope, da sauransu. Dandalin gwajin gani shi ma ya zama dole a yi amfani da shi a gwaje-gwajen bincike na kimiyya.

-

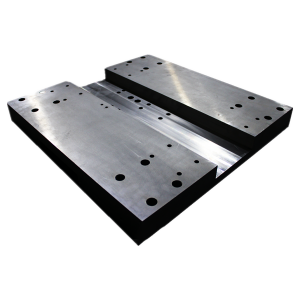

Daidaici Simintin ƙarfe saman farantin

Farantin saman ƙarfe mai kauri T kayan aiki ne na aunawa na masana'antu wanda galibi ake amfani da shi don ɗaure kayan aikin. Ma'aikatan benci suna amfani da shi don gyara, shigarwa, da kuma kula da kayan aikin.

-

Tallafin da za a iya cirewa (Tallafin ƙarfe da aka haɗa)

Tsaya - Don dacewa da Faranti na Dutse (1000mm zuwa 2000mm)

-

Tsarin Farantin Sama mai tsarin hana faɗuwa

An tsara wannan tallafin ƙarfe don farantin duba granite na abokan ciniki.

-

Saitin Jack don Farantin Dutse na Dutse

Saitin jack don farantin saman granite, wanda zai iya daidaita matakin farantin saman granite da tsayi. Don samfuran da suka fi girman 2000x1000mm, ba da shawarar amfani da Jack (guda 5 don saiti ɗaya).

-

UHPC da aka ƙera (RPC)

Ba a iya hango yawan aikace-aikacen fasahar zamani ta UHPC ba tukuna. Mun kasance muna haɓakawa da ƙera mafita waɗanda masana'antu suka tabbatar da ingancinsu ga masana'antu daban-daban tare da haɗin gwiwar abokan ciniki.

-

Gadon Injin Ciko Ma'adinai

An cika ƙarfe, walda, harsashin ƙarfe, da simintin simintin da aka haɗa da resin epoxy mai rage girgiza.

Wannan yana ƙirƙirar tsarin haɗin gwiwa tare da kwanciyar hankali na dogon lokaci wanda kuma yana ba da kyakkyawan matakin tsauri mai tsauri da tsauri.

Haka kuma ana samunsa tare da kayan cikawa masu sha da radiation

-

Ma'adinai Gyare-gyare Injin Gado

Mun sami nasarar wakilci a masana'antu daban-daban tsawon shekaru da yawa tare da kayan aikin da aka ƙera a cikin gida waɗanda aka yi da simintin ma'adinai. Idan aka kwatanta da sauran kayan aiki, simintin ma'adinai a cikin injiniyan injiniya yana ba da fa'idodi da yawa masu ban mamaki.

-

MA'ADANAI MAI KYAU DA AKA YI DA DINKI

Zane-zanen ma'adinai na ZHHIMG® don gadajen injina masu inganci da kayan aikin gado na injina, da kuma fasahar ƙira ta zamani don daidaito mara misaltuwa. Za mu iya ƙera nau'ikan injinan zane-zanen ma'adinai iri-iri tare da daidaito mai kyau.

-

Daidaitaccen Jefawa

Simintin daidaitacce ya dace da samar da simintin da ke da siffofi masu rikitarwa da daidaito mai girma. Simintin daidaitacce yana da kyakkyawan ƙarewa a saman da daidaiton girma. Kuma yana iya dacewa da ƙarancin adadin buƙatun. Bugu da ƙari, a cikin ƙira da zaɓin kayan simintin, simintin daidaitacce yana da babban 'yanci. Yana ba da damar nau'ikan ƙarfe ko ƙarfe mai ƙarfe da yawa don saka hannun jari. Don haka a kasuwar simintin, simintin daidaitacce shine simintin inganci mafi girma.

-

Injin ƙarfe mai daidaici

Injinan da aka fi amfani da su sun kama daga injin niƙa, injinan lathes zuwa nau'ikan injinan yanke iri-iri. Ɗaya daga cikin halayen injinan daban-daban da ake amfani da su a lokacin injinan ƙarfe na zamani shine gaskiyar cewa motsi da aikinsu yana ƙarƙashin ikon kwamfutoci waɗanda ke amfani da CNC (sarrafa lambobi na kwamfuta), wata hanya mai mahimmanci don cimma sakamako mai kyau.