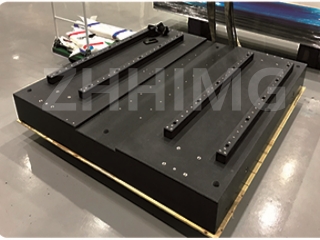

Granite abu ne na halitta wanda aka yi amfani dashi sosai a masana'antar masana'anta don tushen injin.An san sansannin injinan Granite don tsayin daka, dorewa, da kyawawan kaddarorin damping na girgiza, wanda ya sa su zama kyakkyawan zaɓi don aikace-aikacen injina masu inganci.Ɗaya daga cikin irin waɗannan aikace-aikacen da aka fi amfani da sansanonin granite shine na'urorin binciken panel na LCD, waɗanda ake amfani da su don ganowa da kuma nazarin lahani a cikin bangarori na LCD kafin a haɗa su cikin na'urorin lantarki.

Zane da gina na'urar duba panel LCD na buƙatar babban matakin daidaito, kwanciyar hankali, da daidaito.Duk wani rawar jiki ko motsi yayin binciken kwamitin na iya haifar da kurakuran aunawa, wanda zai haifar da sakamako mara kyau da kurakuran samarwa masu tsada.Yin amfani da tushe na injin granite zai iya taimakawa wajen kawar da waɗannan batutuwa da inganta aikin gaba ɗaya da daidaito na na'urar dubawa.Anan akwai wasu hanyoyi don amfani da sansanonin injin granite yadda ya kamata don na'urar duba panel LCD:

1. Yi amfani da tushe na injin granite mai inganci

Don tabbatar da daidaito da kwanciyar hankali na na'urar dubawa, yana da mahimmanci a yi amfani da ginshiƙan injin granite masu inganci, waɗanda aka kera su zuwa daidaitattun ma'auni.Gilashin da aka yi amfani da shi a cikin tushe na inji ya kamata ya kasance mai inganci kuma ba tare da ɓarna ko wasu lahani waɗanda zasu iya rinjayar aikin sa ba.Ya kamata saman tushe na injin ya zama lebur kuma har ma, ba tare da ɓata lokaci ko ƙwanƙwasa wanda zai iya haifar da rashin kwanciyar hankali yayin aikin dubawa ba.

2. Shirya ƙirar tushe na injin

Ya kamata a tsara tsarin ginin injin a hankali, la'akari da ma'auni na bangarori na LCD da za a duba, nau'in kayan aikin dubawa, da kuma izinin da ake bukata don masu aiki suyi aiki.Ya kamata a tsara tushen injin don samar da matsakaicin kwanciyar hankali da rage duk wani girgiza ko motsi yayin aikin dubawa.Tushen ya kamata ya zama babban isa don saukar da bangarorin LCD cikin kwanciyar hankali kuma ya ba da damar samun sauƙin shiga kayan aikin dubawa.

3. Yi la'akari da ƙara abubuwan damping vibration

A wasu lokuta, amfani da abubuwan damping na girgiza, kamar roba ko abin toshe kwalaba, na iya zama dole don ƙara rage duk wani girgiza ko motsi yayin aikin dubawa.Ana iya ƙara waɗannan kayan zuwa tushen injin ko tsakanin kayan aikin dubawa da tushe don taimakawa ɗaukar duk wani girgiza ko girgiza.Ƙarin irin waɗannan abubuwa na iya taimakawa wajen inganta cikakkiyar daidaito da amincin na'urar dubawa.

4. Kulawa na yau da kullun

Kulawa na yau da kullun na tushen injin yana da mahimmanci don tabbatar da cewa ya kasance cikin yanayi mai kyau kuma yana aiki a mafi kyawun matakai.Ya kamata a tsaftace tushen injin akai-akai don cire duk wani datti ko tarkace wanda zai iya shafar aiki.Duk wani tsaga ko wasu lahani yakamata a gyara su da sauri don tabbatar da cewa gindin injin ɗin ya tsaya tsayin daka da dogaro.

A ƙarshe, yin amfani da sansanonin na'ura na granite na iya inganta haɓaka aiki da daidaito na na'urorin binciken panel na LCD.Ta hanyar zaɓar mafi girman ingancin granite da kuma tsara tsarin ƙirar injin injin, ƙara abubuwan damping na girgizawa inda ya cancanta da kiyayewa na yau da kullun zai haifar da haɓaka haɓaka aiki yayin rage yawan kurakuran samarwa.

Lokacin aikawa: Nov-01-2023