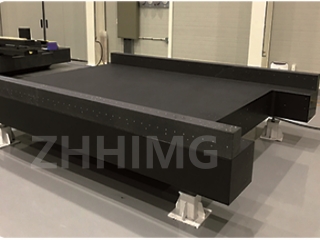

Granite ya kasance sanannen zaɓi don tushe a cikin sarrafa Laser saboda kyakkyawan ƙarfinsa, kwanciyar hankali, da kaddarorin juriya.A cikin wannan labarin, za mu bincika abũbuwan amfãni da rashin amfani na granite a matsayin tushe abu ga Laser aiki.

Amfanin Granite

1. Durability: Granite dutse ne mai banƙyama na halitta wanda ke da kyakkyawan tsayin daka ga lalacewa da tsagewa, tarkace, da sauran lalacewar jiki.Wannan fasalin ya sa ya zama abin dogaro kuma mai dorewa don injin sarrafa Laser.

2. Ƙarfafawa: Ƙarfafawar Granite wani mahimmanci ne mai mahimmanci don sarrafa laser, kamar yadda ya tabbatar da matakin da ake bukata na daidaitattun tsarin aiki.Abubuwan gabaɗaya suna da juriya ga zafi, lalata sinadarai, da haɓakar thermal, yana mai da shi tabbatacce kuma zaɓi mai dogaro ga tushe na injin sarrafa Laser.

3. Vibration-resistance: Granite shine kyakkyawan zaɓi don sarrafa Laser saboda yanayin juriya-juriya.Girgizar da na'urar Laser ke haifarwa na iya haifar da kurakurai da rashin daidaituwa a cikin aiki, amma tushen granite yana taimakawa wajen rage waɗannan girgizar da kuma kula da kwanciyar hankali na injin.

4. Iya Shakar Ƙarfin Ƙarfafawa: Granite yana da ikon ɗaukar makamashin thermal, wanda shine wani muhimmin fasali a cikin sarrafa Laser.Lokacin da Laser ke aiwatar da wani abu, yana haifar da babban adadin zafi, wanda zai iya haifar da haɓakar abu da kwangila.Idan tushe ba zai iya ɗaukar wannan makamashi na thermal ba, zai iya haifar da kuskure a cikin tsari.Ƙarfin granite don ɗaukar wannan makamashi na thermal yana taimakawa wajen tabbatar da daidaiton aikin laser.

5. Aesthetically Appealing: A ƙarshe, granite abu ne mai kyau wanda zai iya ba da kyan gani da kyan gani ga injin sarrafa Laser.Wannan fasalin zai iya taimakawa inganta bayyanar na'ura kuma ya ba da kyakkyawan ra'ayi ga abokan ciniki da baƙi.

Rashin amfanin Granite

1. Rashin malleability: Granite abu ne na halitta kuma mai tsauri kuma ba za a iya ƙera shi ko lankwasa shi cikin siffofi na al'ada ba.Wannan yanayin yana nufin cewa ƙila bazai dace da kowane nau'in injunan sarrafa Laser ba kuma ana iya gyara shi bisa ƙayyadaddun buƙatun na'urar.

2. Heavy: Granite abu ne mai yawa kuma mai nauyi wanda ke da kalubale don jigilar kaya da shigarwa.Shigar da tushe na granite yana buƙatar ƙungiya ta musamman da kayan aiki don amintaccen wuri mai inganci.

3. Kudin: Granite abu ne mai tsada mai tsada wanda zai iya ƙara yawan farashin injin gabaɗaya.Farashin na iya zama mai ma'ana, duk da haka, la'akari da ingantacciyar inganci, daidaito, da dorewar injin sarrafawa.

Kammalawa

A ƙarshe, abũbuwan amfãni daga granite a matsayin tushe abu a cikin Laser aiki fiye da disadvantages.Dorewa, kwanciyar hankali, da kaddarorin juriya na granite suna ba da ingantaccen aiki da daidaito yayin rage kurakurai da rashin daidaituwa.Granite na iya ɗaukar makamashin thermal, yana tabbatar da matakin da ake buƙata na daidaito kuma yana da daɗi.Ko da yake farashin granite na iya zama mafi girma fiye da sauran kayan, har yanzu yana da zuba jari mai mahimmanci saboda dukiyarsa mai dorewa.

Lokacin aikawa: Nuwamba-10-2023